air cleaners

|

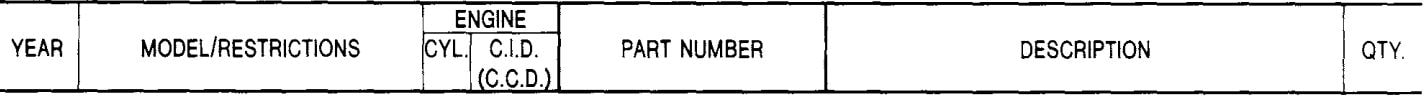

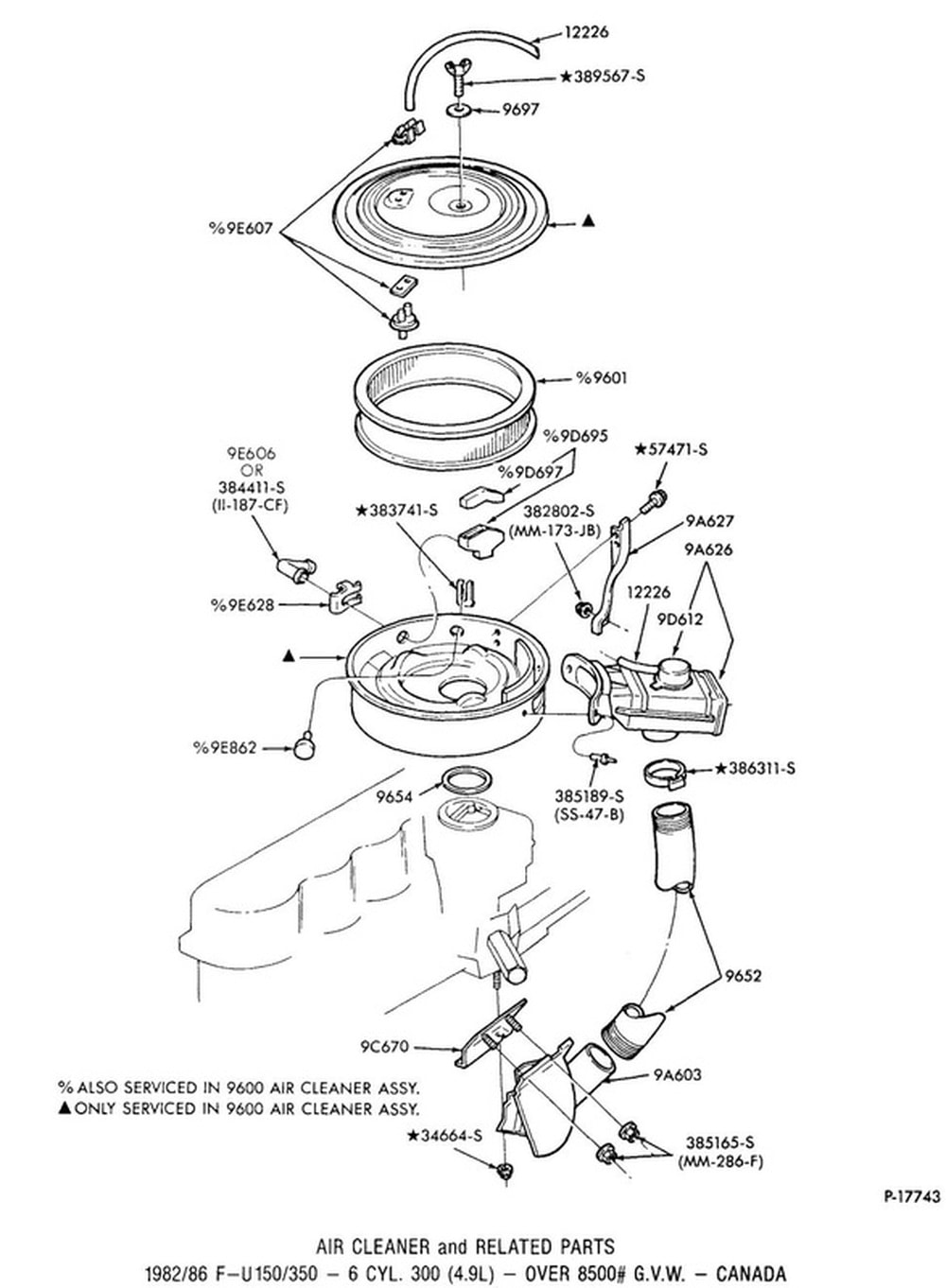

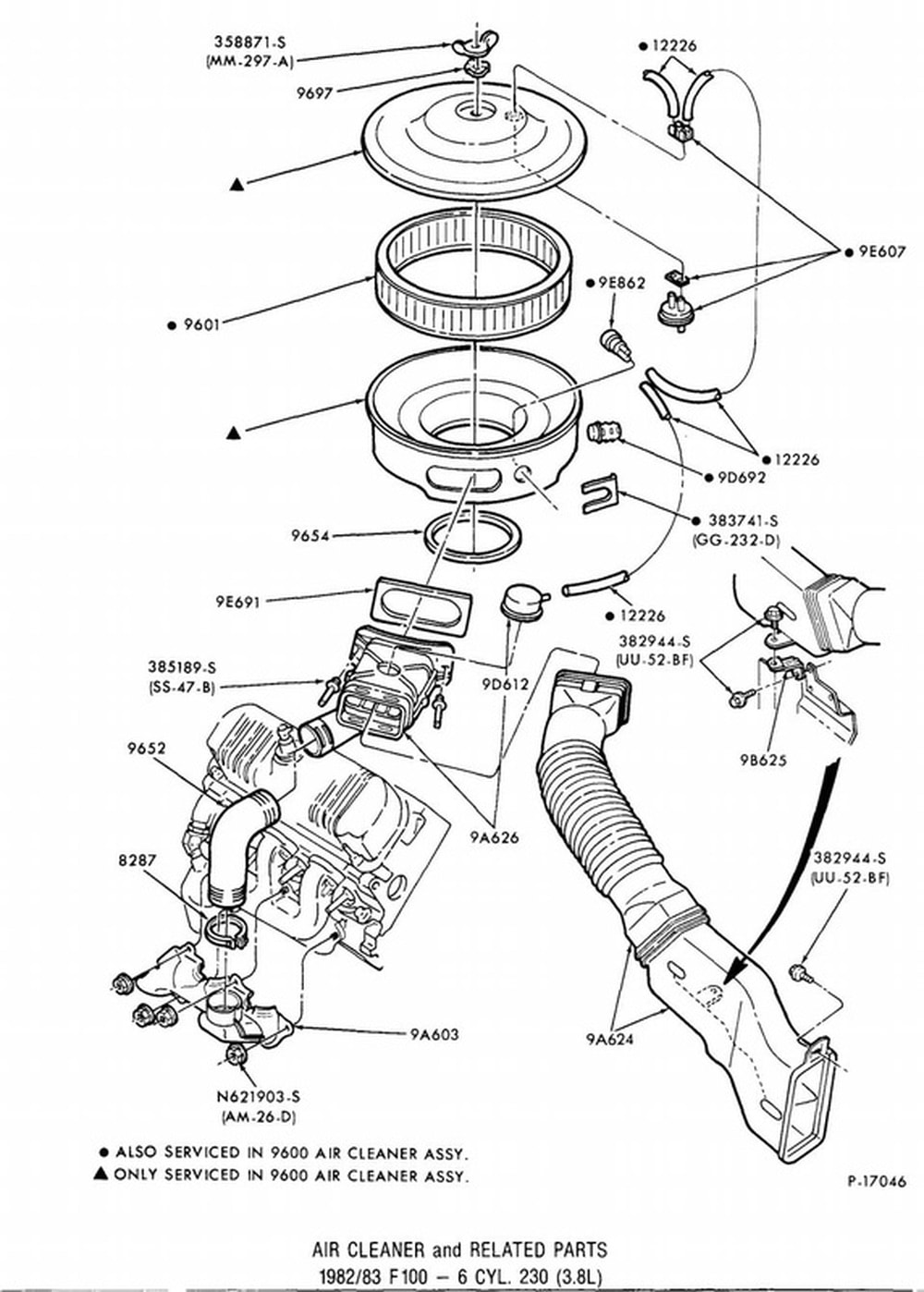

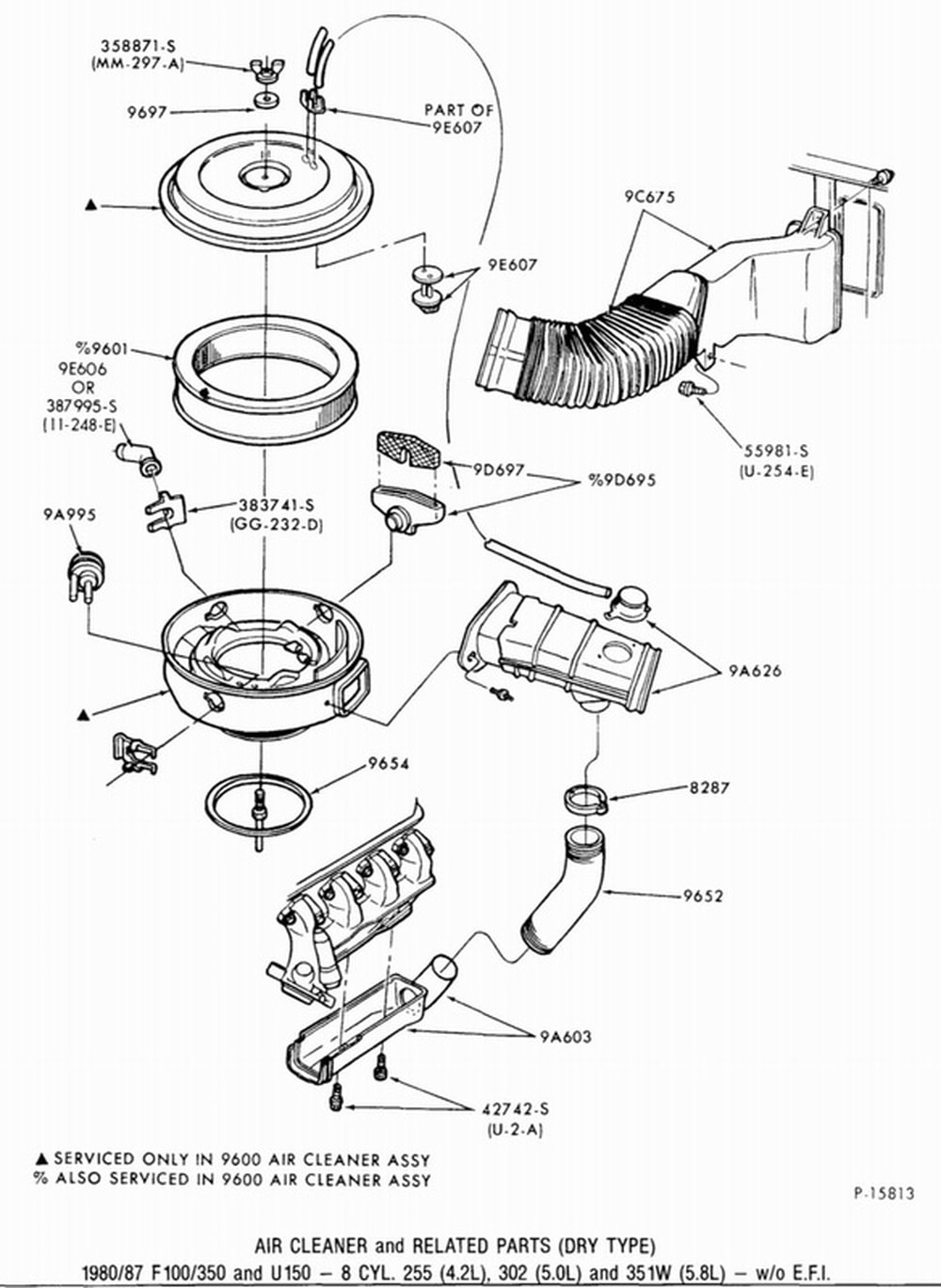

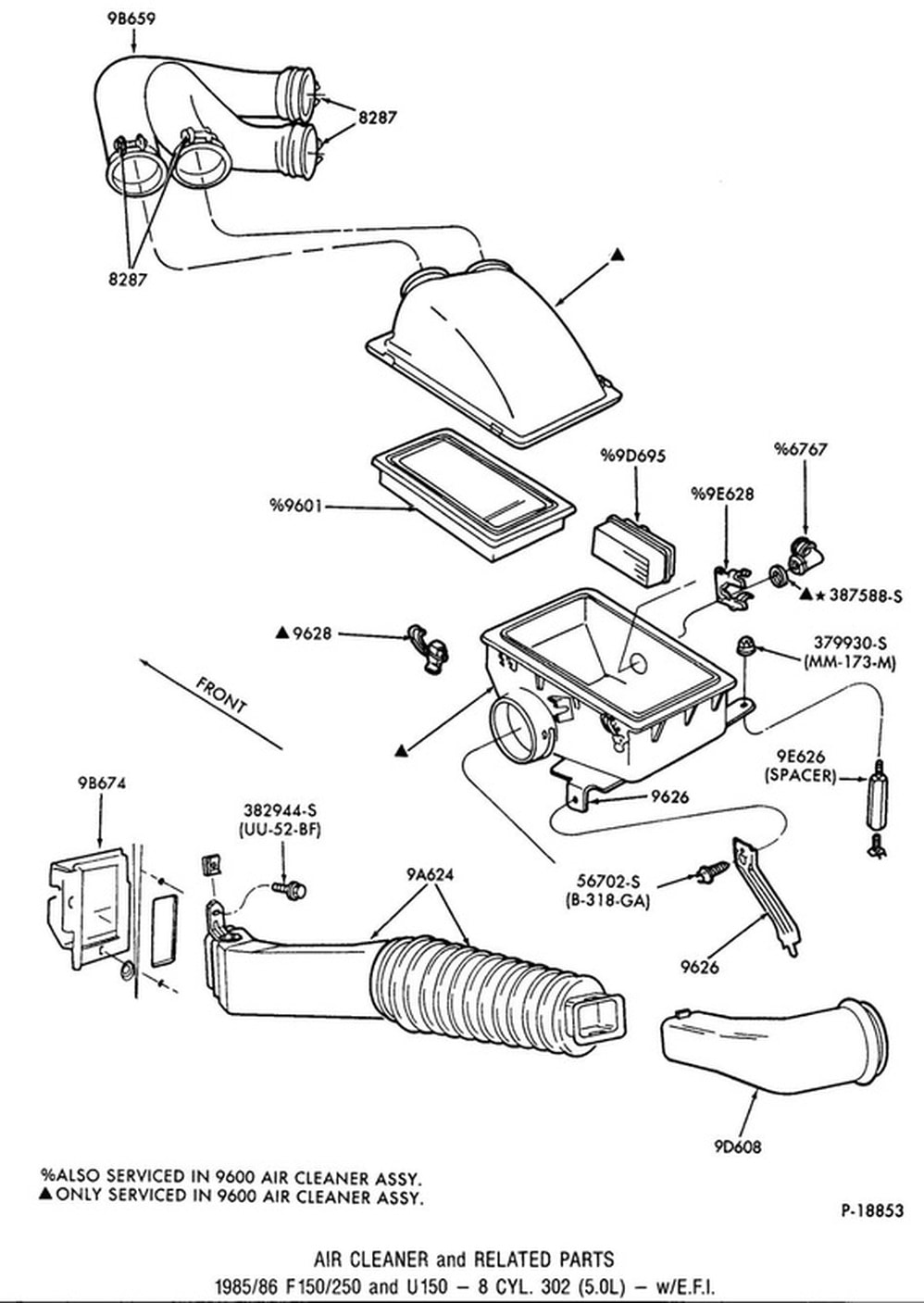

Air cleaners like the Edelbrock on the right sure do look good and sound great when the secondaries open on a 4bbl. However, replacing the stock air cleaner on one of these trucks, or any vehicle with a carb, is a really bad move. That is because the widely varying air temp that reaches the carb causes several problems.

|

First is a changing air/fuel ratio. A carb is a remarkable device, but it cannot adjust for differing air temps. Since the air/fuel ratio is really the ratio of oxygen molecules to gasoline molecules, and since the number of oxygen molecules per volume of air changes dramatically with the temp, the air/fuel ratio does as well. Put another way, the only way to hold a constant AFR with a carb is to maintain the inlet air temp at some constant. But, according the the Carb Facts and Correcting Myths web site, underhood temps can go as high as 240 degrees, and that's exactly the air you pull into the carb with an open element cleaner. And, in winter the inlet air temp can be closer to zero.

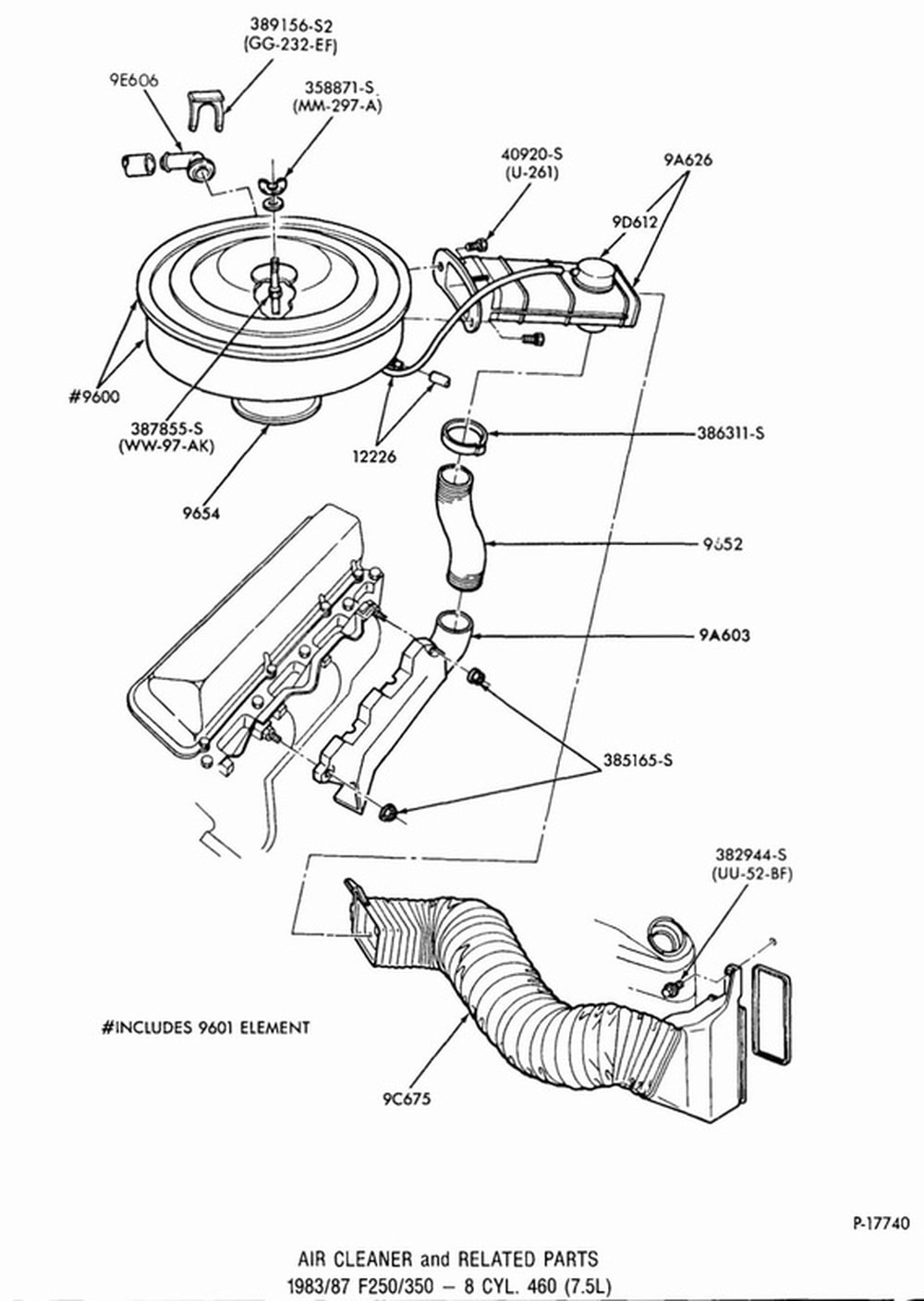

Second, since colder, more dense air creates more power, it makes little sense to feed the engine 240 degree air when you can get it down to more like 120 degrees with the stock air cleaner and associated plumbing. How can that be? Well, the stock air cleaner has a duct that connects to the radiator support, which means it pulls air from ahead of the radiator. So the engine is breathing much cooler air than under-hood air which is heated by the radiator, exhaust manifolds, and all of the accessories.

Second, since colder, more dense air creates more power, it makes little sense to feed the engine 240 degree air when you can get it down to more like 120 degrees with the stock air cleaner and associated plumbing. How can that be? Well, the stock air cleaner has a duct that connects to the radiator support, which means it pulls air from ahead of the radiator. So the engine is breathing much cooler air than under-hood air which is heated by the radiator, exhaust manifolds, and all of the accessories.

|

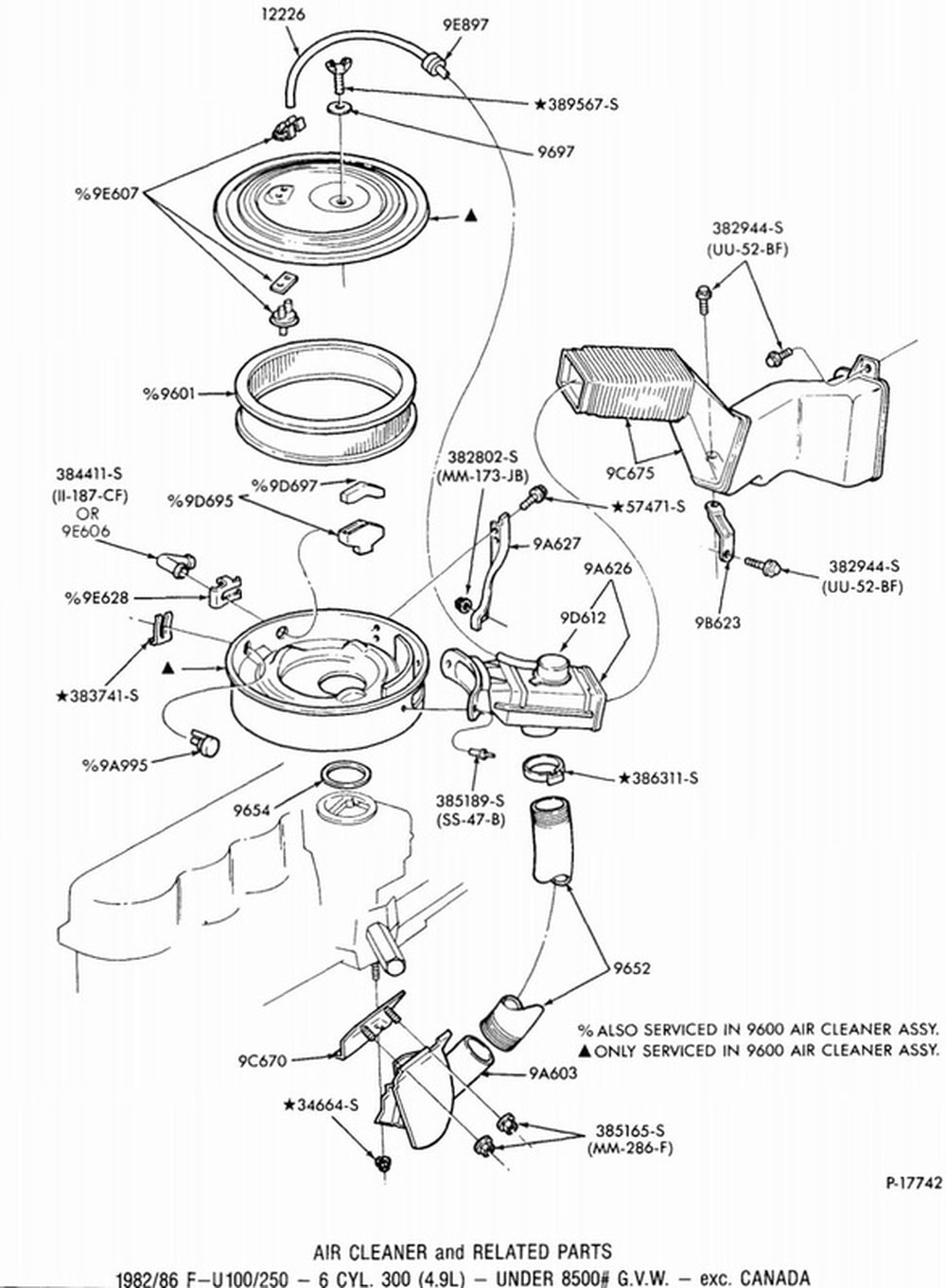

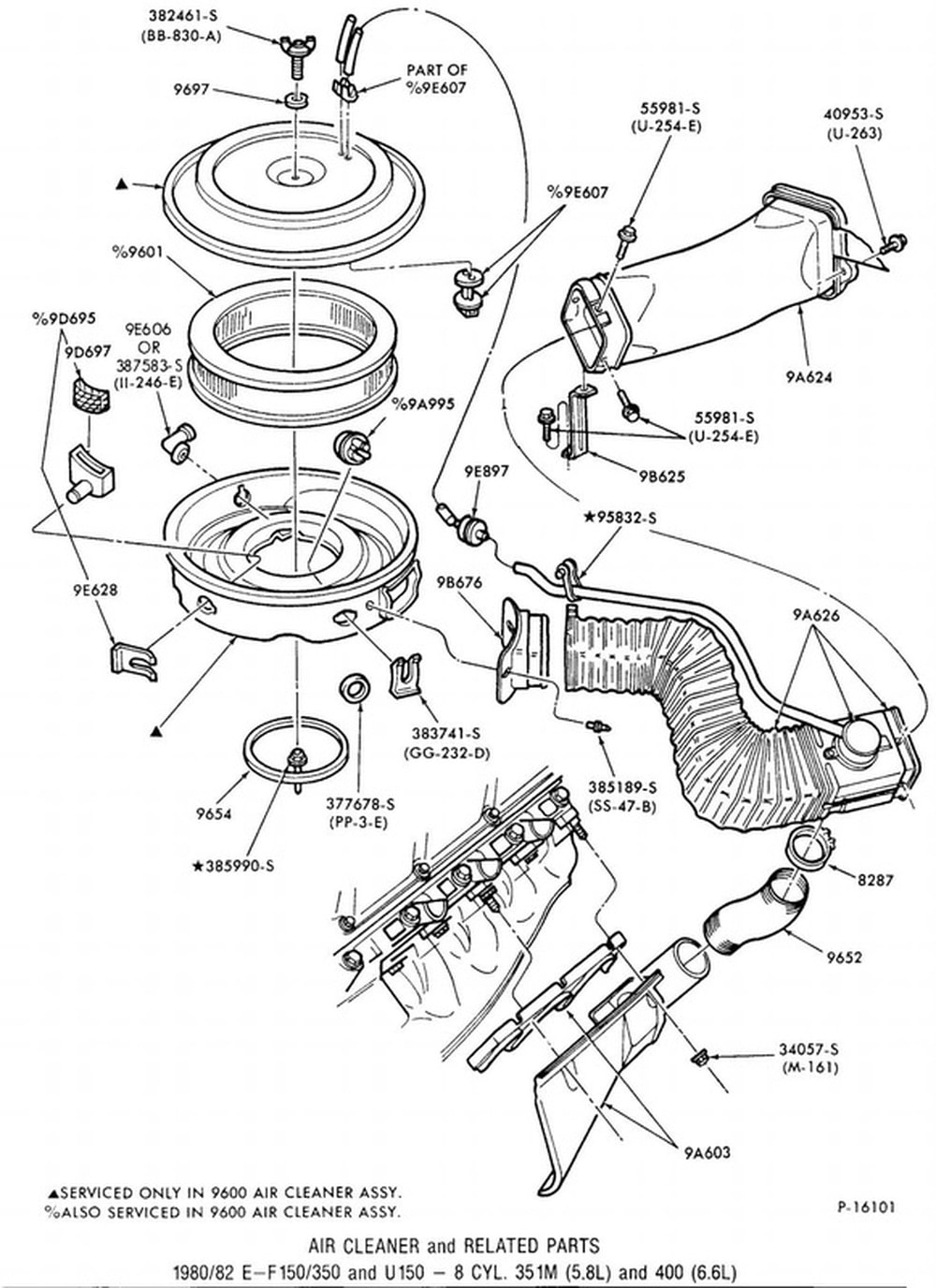

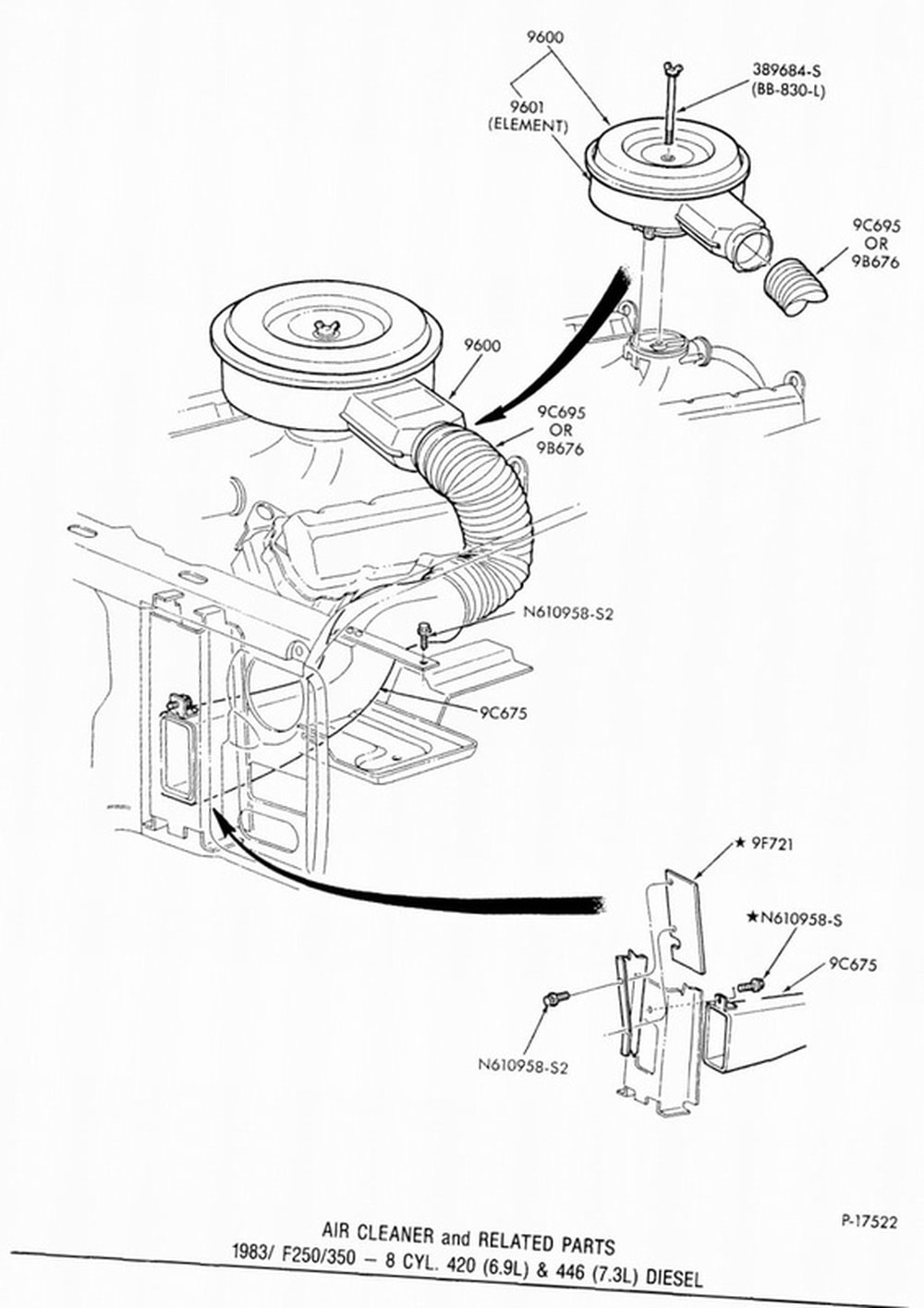

And third there's winter driving where carb icing is a significant problem that the stock air cleaner solves. That's because there's a shroud around the exhaust manifold that channels hot air to the air cleaner very quickly after startup. But, wouldn't that mean you'd have really hot air to the carb in the summer? No, not with the simple-but-effective factory system, like the one on the right.

|

The following pages are from a Mityvac owner's manual and they explain how the heated-inlet air system works and how to test it.

|

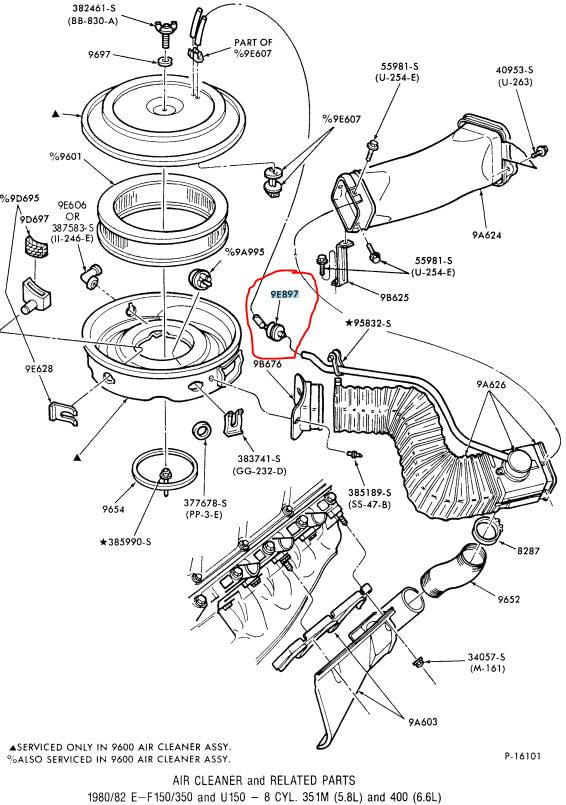

Check valves were used in many places in the vacuum systems on these trucks, and one place was on the air cleaner to keep the vacuum to the vacuum motor that controlled the air temp to the carb. One example of that is in the illustration to the right.

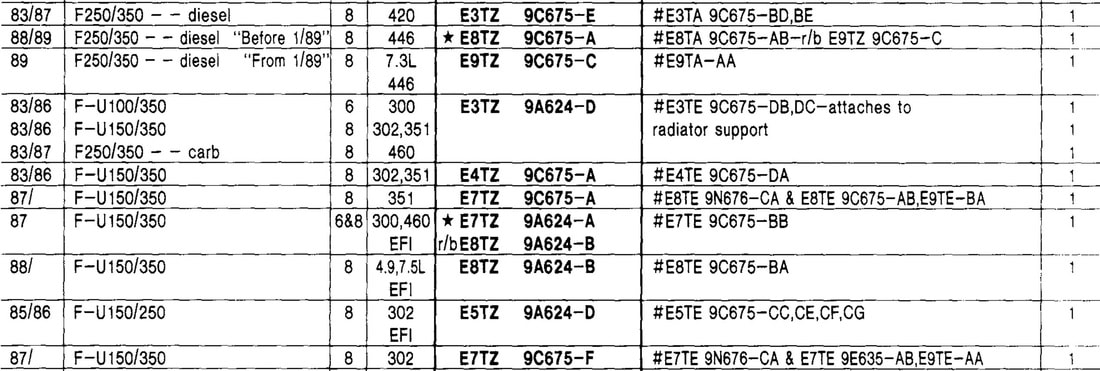

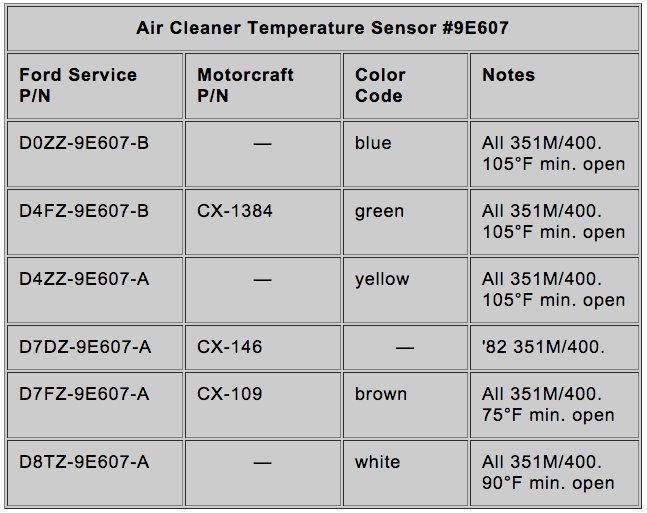

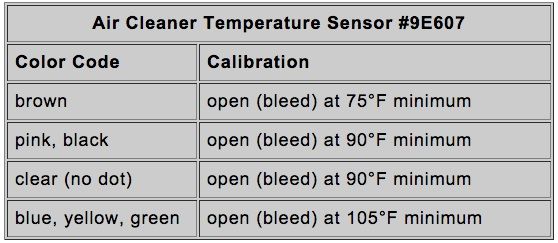

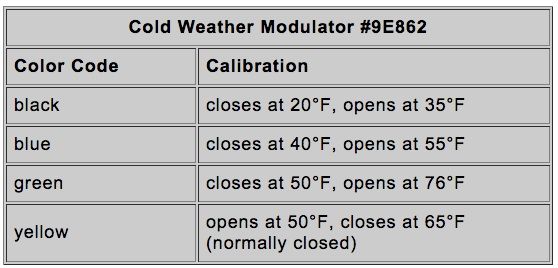

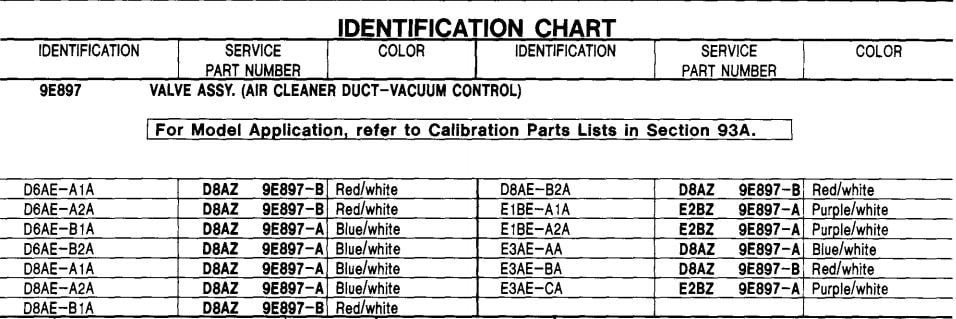

The basic part number to that part is 9E697, but in order to find one you need the full part number. However, there are two ways to find the full part number: by looking it up in the calibration parts list for your specific application, or reading the number or color code on the one you have. But the calibration parts list approach isn't easy, so I suggest using the code on your part. And toward that end the cross reference below on the left should help. |