CARTER YF & YFA 1BBL cARBS

Factory rebuilding instructions, exploded views, part #'s, and tuning tips for the Carter YF & YFA carburetors.

1980 - 86 FORD TRUCKS:

FUEL SYSTEMS

AIR CLEANERS

CARBURETORS, CHOKES, & EFI

CHOKES

CARTER YFA 1BBL

EFI

HOLLEY 4180C

MOTORCRAFT 2150

MOTORCRAFT 7200 VV

FUEL SYSTEM ILLUSTRATIONS

FUEL SYSTEM PART #'S

FUEL SYSTEMS

AIR CLEANERS

CARBURETORS, CHOKES, & EFI

CHOKES

CARTER YFA 1BBL

EFI

HOLLEY 4180C

MOTORCRAFT 2150

MOTORCRAFT 7200 VV

FUEL SYSTEM ILLUSTRATIONS

FUEL SYSTEM PART #'S

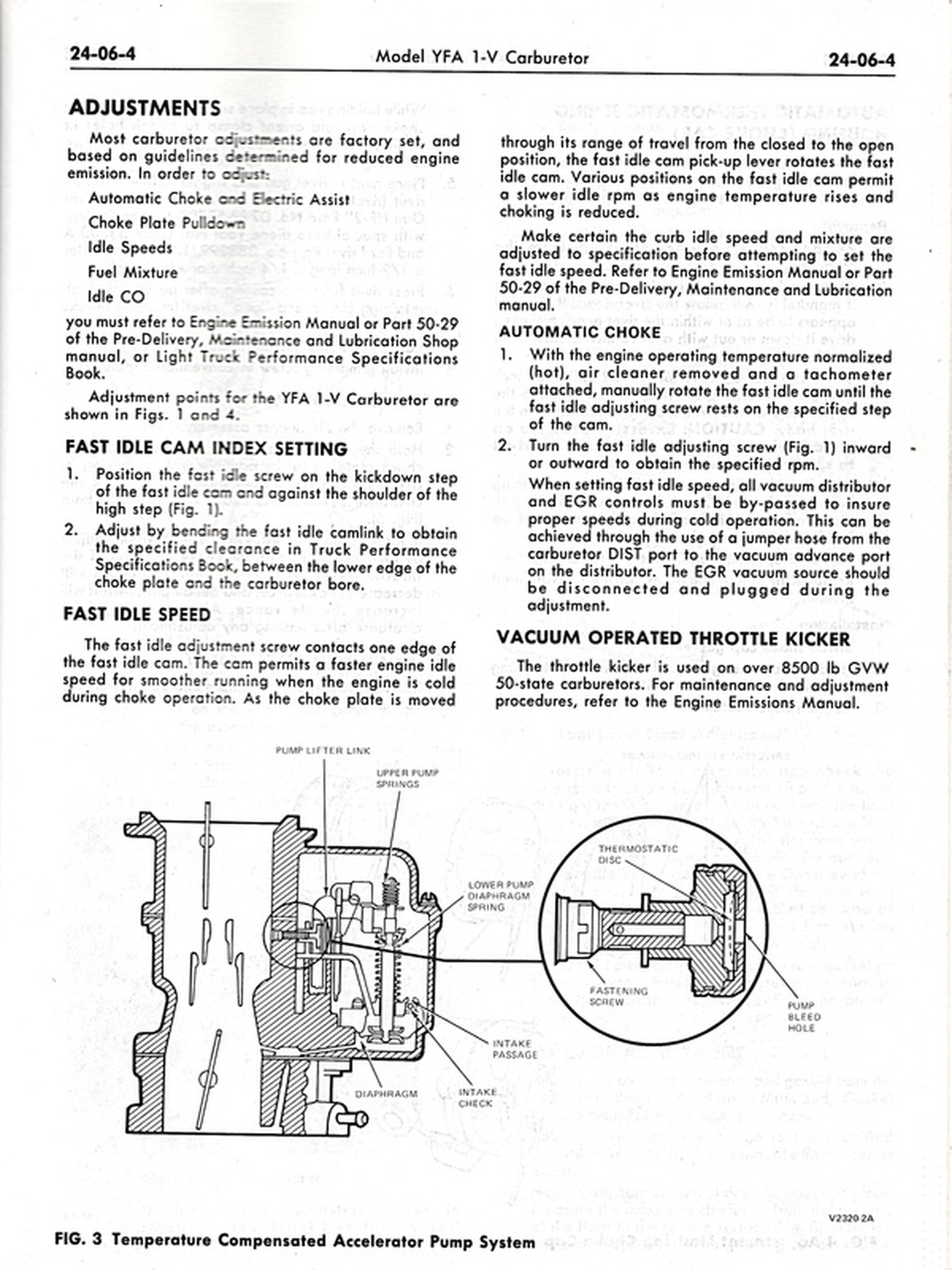

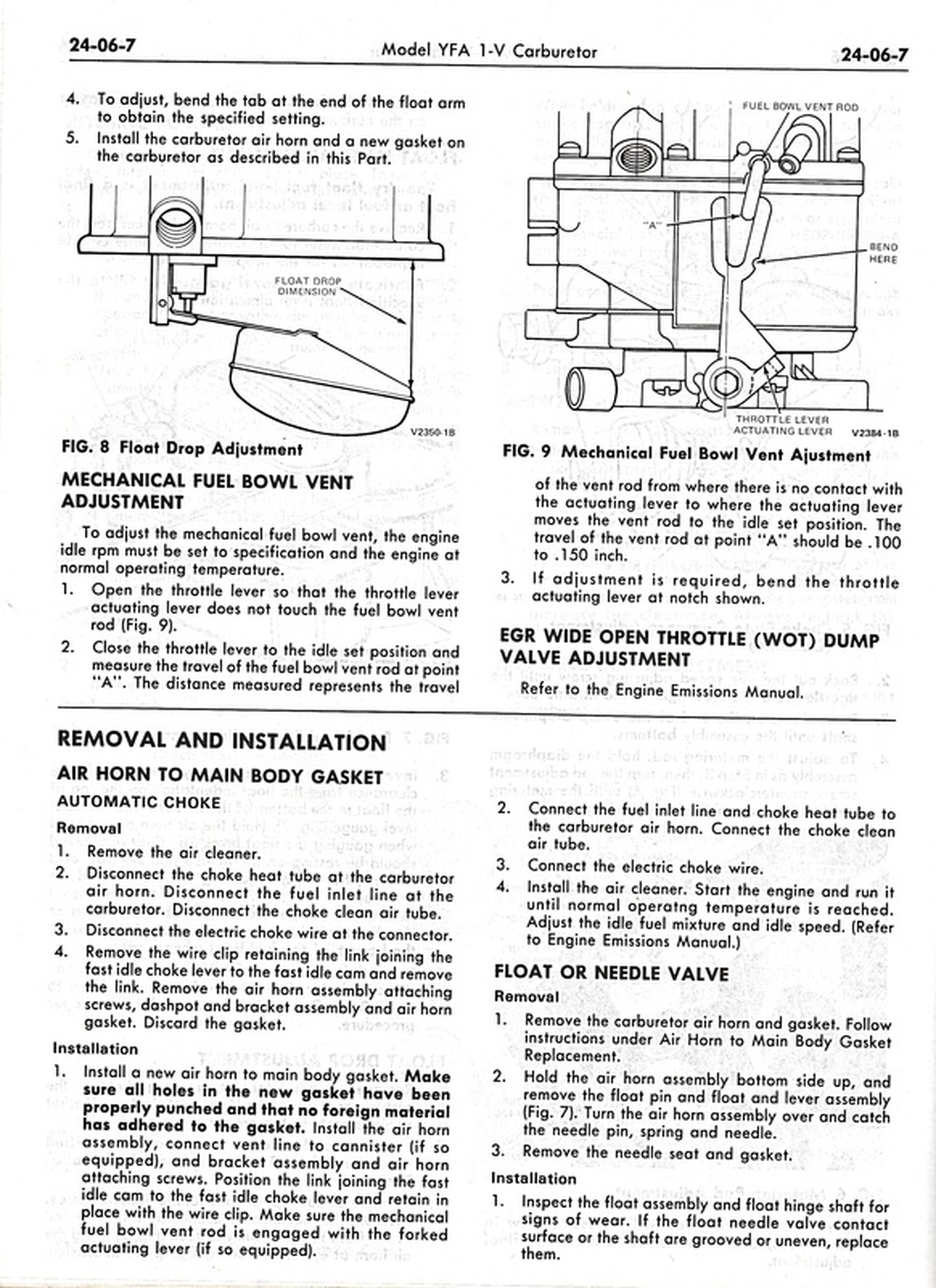

There is more information regarding this carburetor's adjustments in the 1985-1986 Fuel System Adjustments booklet.

The following tips are from Bill Vose:

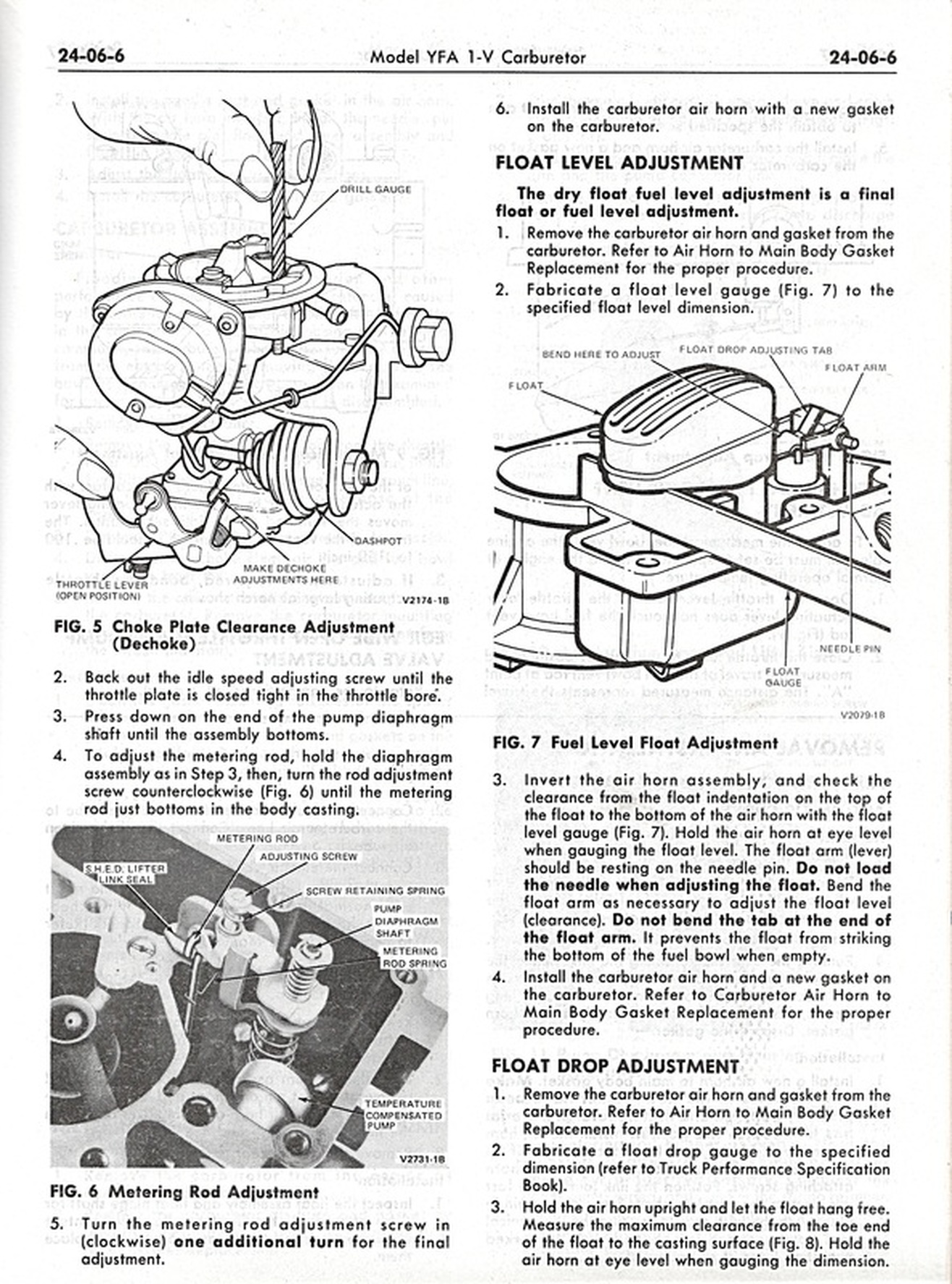

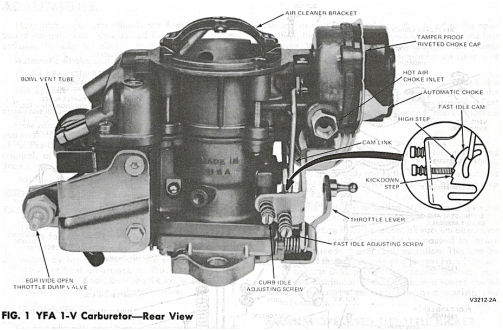

- The Carter YFA is a fairly simple carburetor, which has one major weak point - the combination accelerator pump and metering rod control. This is a diaphragm with manifold vacuum on bottom and fuel on the top side. When this diaphragm fails the fuel is drawn directly into the intake.

- The other very common issue with the YFA is the throttle body to float bowl joint. The original screws are what is called “prevailing torque” and appear almost triangular when viewed from the end, the problem arises with the alloy the float bowl and air horn are made from, it is a zinc alloy commonly called “pot metal” and creeps with age and heat. The end result is the screws loosen and the gasket becomes torn or worn and begins to leak so the vacuum no longer holds the diaphragm down and the carburetor starts running rich. The other problem was the vibration of the six cylinder engine helping to loosen the screws.

- When rebuilding these it is important to use Loctite on these screws to prevent them from loosening. If the truck has a large asymmetric air filter with a brace to the cylinder head it needs to be properly assembled so there is no off center load on the carburetor. Inside the float bowl is an adjusting screw that is used to properly “tune” the mixture for emissions, there is a setting procedure in the rebuilding and there is a hole in the air horn above this screw closed by a small aluminum disc plug. The screw can be adjusted through this hole with a slender Phillips screwdriver. Clockwise is richer counterclockwise is leaner.

- The feedback system used on the 1985-1986 models consists of a duty cycle solenoid that “trims” the idle and main air bleeds, there is a throttle position sensor and a stepper motor for idle speed control, this also incorporates an idle position switch. As a result idle adjustments are a bit different on these.

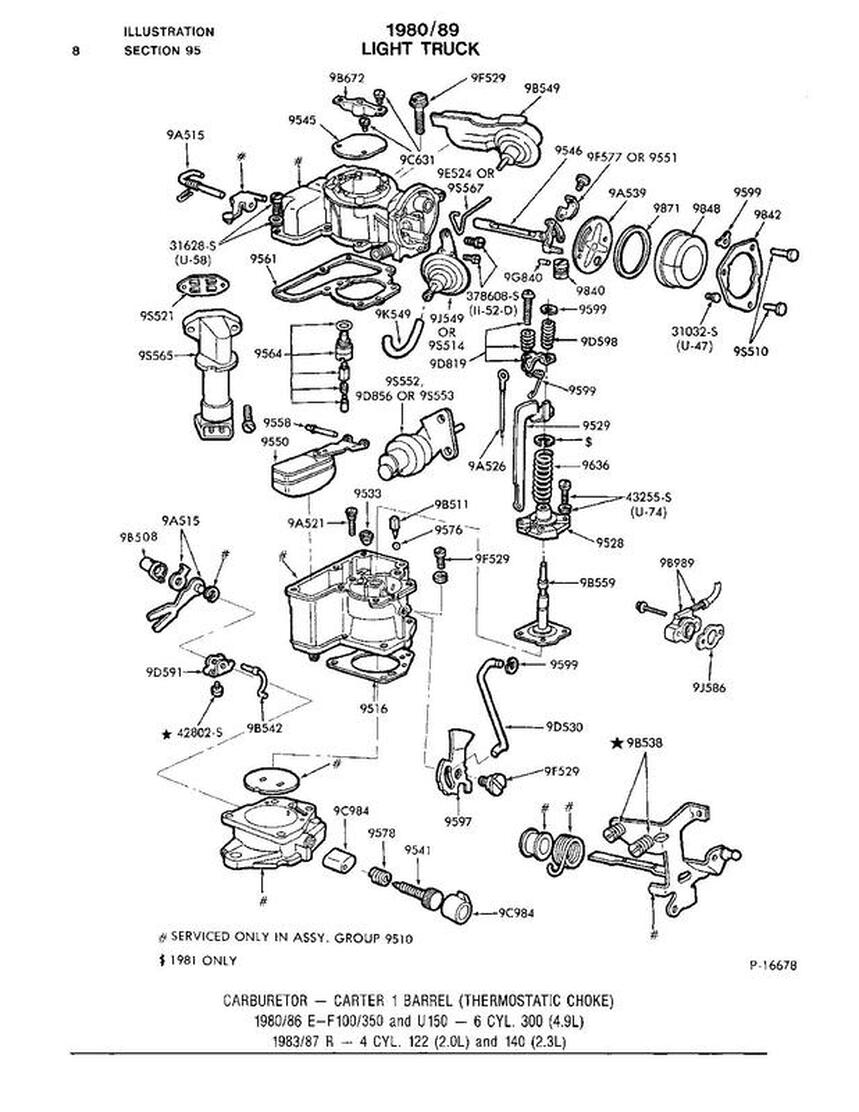

How To Use This Document: To use this document you need a carburetor part number starting with "95.1". If you don't have that then go to the page entitled CALIBRATION INFO & PART #'S to get it for your truck.

Let's assume that # is 95.1A. In that case your carb gets the parts called out with an "A" in column "A", below, and so on for B through M. But if it is 95.1N or after you'll have to scroll down and find the applicable page.

Let's assume that # is 95.1A. In that case your carb gets the parts called out with an "A" in column "A", below, and so on for B through M. But if it is 95.1N or after you'll have to scroll down and find the applicable page.